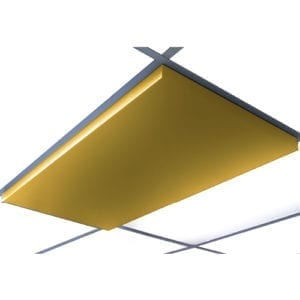

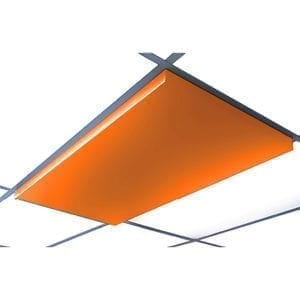

Description

ELPs provide an extremely rugged noise control system for schools, colleges, universities and learning academies. From classrooms and hallways to music practice and staff offices, specially strengthened ELP panels and fastner systems are ideally suited for correcting noise and reverb problems where people gather or work, including Pools & Recreational Facilities, Theatres & Auditoriums, Music Schools & Private Academies, as well as other applications.