Description

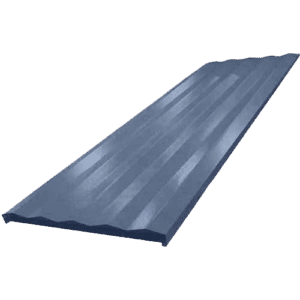

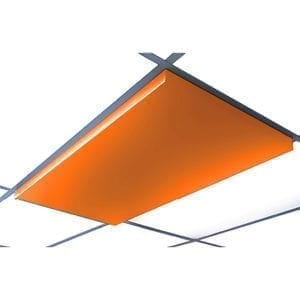

Flat Functional Panels improve the acoustic environments in facilities where a “level of quietness” is required to be achieved without compromising the room’s visual attractiveness. For high humidity applications such as indoor pools or where panels may be exposed to oils or vapours, or for installation in dust-free clean rooms, the 2″ (51mm) thick, fine fibered, fibrous glass acoustical insulation may be enclosed in 1.5-2 mil flameguard polywrap. All EFP Types are available in 4′ (1.2m), 5′ (1.5m), 6′ (1.8m), 8′ (2.4m), and 10′ (3.0m) sizes, permitting application inlarge or small spaces, as well as, restricted areas. Standard panel size is 10′ (3.0m).