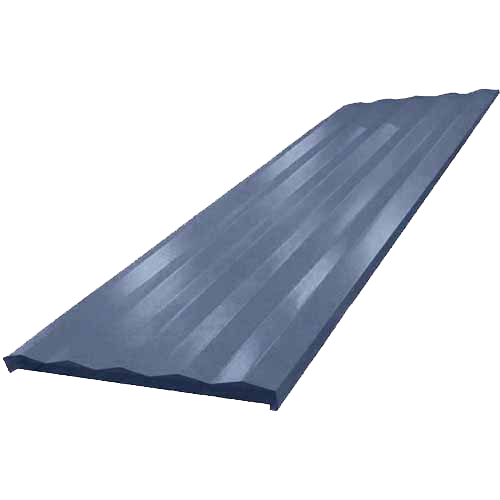

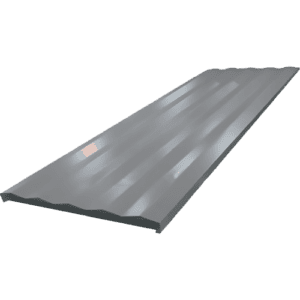

Description

EFPs are attractive, sound absorbing, fire-resistant panels which can be spot located on walls and ceilings to achieve effective noise control. Since EFPs are independent panels, they can be fastened into place without disturbing existing utilities. This functional approach to acoustic control is less expensive than continuous ceiling or wall treatment.EFPs help solve a number of noise control problems. They can be added to barriers to increase noise reduction capability. Special aluminum EFPs, for example, have been attached to concrete barrier walls around transformers and waste water treatment plants, thereby enhancing the barriers’ acoustic performance as well as preventing a potential community noise problem.